Almost anything connected with railway operation can be made or mended at Newport Workshops. A small army of skilled tradesmen produces nuts, bolts, screws, and railway carriages, electric trains and steam locomotives! “Spirit of Progress” — including engines and cars — was built at the ‘Shops. So, too, was H 220, one of the largest locomotives in the Commonwealth.

Altogether about 2,700 men (and women) are employed there, in a remarkable variety of trades and professions covering Engineers, Patternmakers, Upholsterers, Painters, Coppersmiths, Blacksmiths, Research Chemists, Trained Nurses, Carpenters, Plumbers, Springmakers, Clerks, Typistes and Labourers.

Roaming alone at Newport, you would soon become completely lost. The ‘Shops comprise a little world of their own, with separate buildings and departments for the various phases of railway making and mending. There is the Erecting Shop, for example, where locomotives are pulled to pieces, repaired and overhauled, and put together again. Attached to it is a caustic boiling-down plant — where the steam hangs all day like a pea-souper fog — for cleaning the bits and pieces, which added together, make up an engine. There’s a Boiler Shop (hot and noisy with a perpetual din and clang), a Foundry, a Patternmaking Shop, a Log Mill, a Saw Mill and a Woodworking Shop. There are Coppersmiths’ and Blacksmiths’ Shops too, and Tarpaulin, Westinghouse Brake, and Steel Construction Shops. And there’s an up-to-date Laboratory, and a modern Ambulance Room. Add to all these the various offices necessary for administration and you have some idea of the size and versality of the Newport Workshops.

But although you would get lost in this strange new world, there is a very clearly defined pattern underlying the activity of the various departments. All the sections dovetail perfectly — almost imperceptibly. You can’t make or mend trains by any haphazard means: there must be keenly controlled activity and a highly organized system.

‘Behind the railway scene’, publicity brochure produced by the Victorian Railways, 1950

Building an N-class locomotive at Newport Workshop, c.1940s

Reproduced courtesy Public Record Office Victoria

The Newport Railway Workshops was established in 1882. It built and maintained everything ‘from state-of-the-art locomotives to the pegs to hold the track in place.’ Between 1893 and 1950 Newport produced more than 500 locomotives, including the famous streamlined, air-conditioned ‘Spirit of Progress’. Other construction included 12 electric locomotives, 34 rail motor cars, 33 trailers, 1,435 carriages, 851 vans and sundry stock, and 13,366 trucks. Newport made many of its own machine tools, a task requiring a high level of technical expertise.

The workshops covered about 130 acres, with buildings occupying 22 acres and railway tracks extending for 33 miles (53 kms). At its peak in the 1920s the workshops employed over 5,000 people. (Another 500 railwaymen worked at the North Melbourne Workshops, where rolling stock was repaired and overhauled.)

During World War II Newport was an important centre of wartime production. Materials supplied to the fighting forces ranged from Bren gun carriers and tugboats to fine screws and surgical instruments. Rear fuselages, tail assemblies, ailerons and elevators for Beaufort and Beaufighter aircraft were turned out; so too were patterns for Diesel engines, components for gun howitzers, shells, and torpedo parts. Labour shortages resulted in a third of the workforce being women, probably the highest proportion at any time at Newport.

Wartime production at Newport Railway Workshops, building an aircraft, September 1940

Reproduced courtesy Public Record Office Victoria

Wartime production at Newport Railway Workshops, building an aircraft, September 1940

Reproduced courtesy Public Record Office Victoria

Construction of aircraft at Newport Railway Workshops, September 1940

Reproduced courtesy Public Record Office Victoria

The introduction of low-maintenance diesel locomotives, outsourcing of rail vehicles to commercial manufacturers and the decline in rail traffic reduced workshop activities and staff. By 1990 only 300 staff were left and the workshops closed in 1992.

Newport was a vast and tremendously busy place… There were car shops for building carriages, a truck shop for wagons, a bush mill to cut whole logs into usable billets of timber… The sawmill also had a bending area, to bend timber to fit the curved roofs and ceilings of the carriages of the day. Newport had a paint shop, where all paints were made, milled, mixed and prepared. Painters were attached to this section to paint carriages, trucks, etc. There was an erection shop, where steam locomotives were built and repaired. A boiler shop where steam boilers were built for locomotives. Also a large foundry, which built loco parts, brake blocks of many types, signal equipment, luggage racks and a hundred other things needed for trains and locomotives. A tarpaulin shop with rows of heavy sewing machines, where sail makers made tarpaulins to cover open goods trucks, wheat cargoes and so on. A laboratory where chemists and engineers tested all the products used. A bolt shop, where the famous ‘dog spikes’ for holding steel rails to wooden sleepers were made. A blacksmiths’ and spring shop, which was also home for a number of large, steam-driven manufacturing and stamping hammers. Numerous stores departments to handle all the needed parts and merchandise, a large office block, and a first-aid department complete with a pair of skilled nursing sisters.

John Monk, quoted in In the service?: a history of Victorian railways workers and their union, 1991

Newport Railway Workshops, car builders, c.1920

Reproduced courtesy Public Record Office Victoria

Newport Railway Workshops, tarpaulin shop, c.1920

Reproduced courtesy Public Record Office Victoria

Newport Railway Workshops, apprentice training, c.1920

Reproduced courtesy Public Record Office Victoria

A trained nurse was stationed in the Ambulance Ward at Newport Railway Workshops from the early 1920s. The nurse attended to men injured in the workshops. On average, 65 men per day were treated, indicative of the dangerous work conditions on site.

Newport Railway Workshops, nurse and patient, c.1915

Reproduced courtesy Public Record Office Victoria

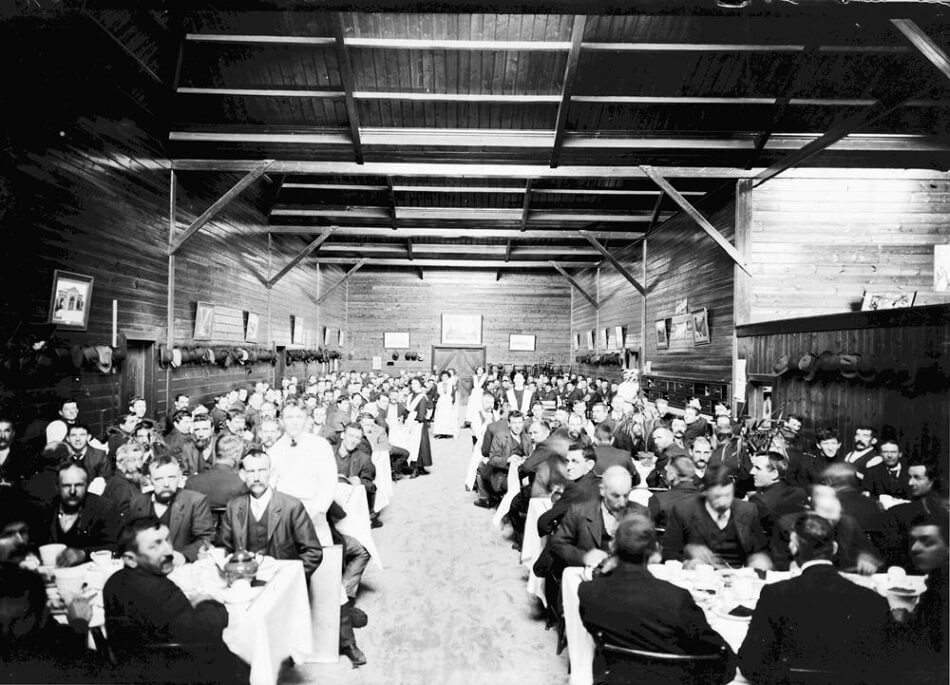

Newport Railway Workshops, dining room, 1912

Reproduced courtesy Public Record Office Victoria

Newport Workshops, dining room at meal time, c.1920s

Reproduced courtesy Public Record Office Victoria

Construction of aircraft at Newport Railway Workshops, September 1940

Reproduced courtesy Public Record Office Victoria